Essential details

| Grade: | 4000 Series |

| Shape: | Square, Round square rectangular hexagon flat |

| Surface Treatment: | Anodized |

| Length: | 1000-12000 mm |

| Usage: | Food Grade, Sanitary, Exhaust, Water, Chimney, Gas |

| Hardness: | HV400 |

| Alloy Or Not: | Is Alloy |

| Temper: | O - H112 |

| Al (Min): | 98.8% |

| Wall Thickness: | 0.5-10mm |

| Model Number: | aluminium pipe |

| Tolerance: | ±1% |

| Processing Service: | Bending, Decoiling, Welding, Punching, Cutting |

| Delivery Time: | 22-30 days |

| Product name: | Metal Al Aluminum Alloy Tube Pipe |

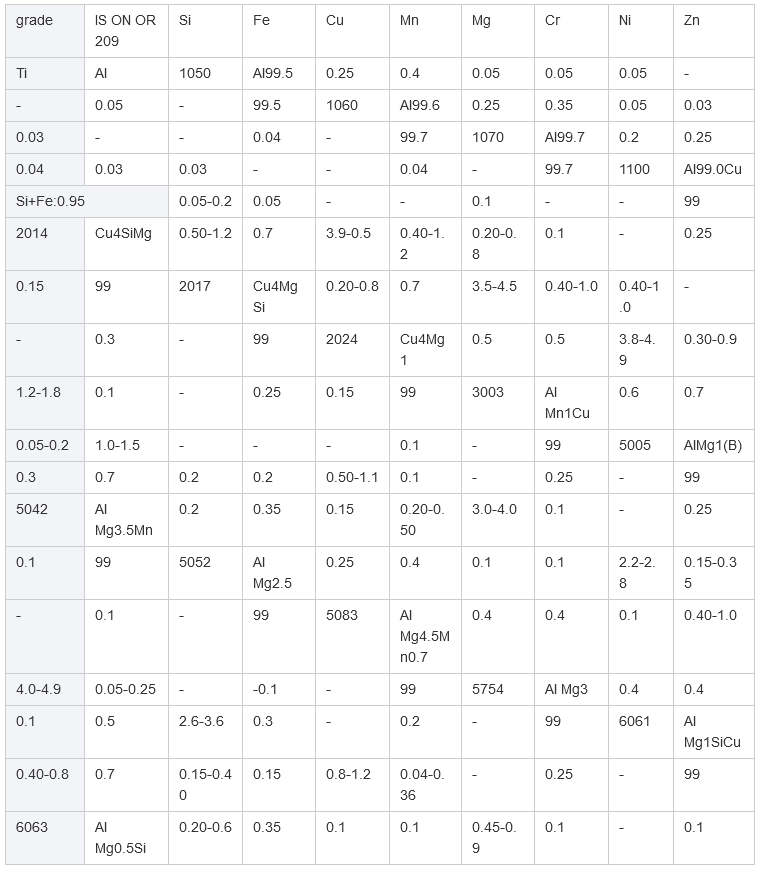

| Alloy grade: | 3003 5052 5083 5086 5754 6061 6063 6082 7072 7075 6063 |

| Advantage: | UV Protection |

| PAYMENT: | Balance |

| Surface finish: | 2B/BA/HAIRLINE/8K/NO.4/No.1 |

| Package: | :Standard Seaworthy Packing |

Product Description

Aluminum pipe is a kind of non-ferrous metal pipe. It refers to the metal tubular material that is extruded from pure aluminum or aluminum alloy to be hollow along its longitudinal length.

There can be one or more closed through-holes, with uniform wall thickness and cross section, which are delivered in a straight or coiled shape. It is widely used in automobile, ship, aerospace, aviation, electrical appliances, agriculture, electromechanical, household and other industries.

Classification

Aluminum pipes are mainly divided into the following types

It is divided into square tube, round tube, patterned tube, special-shaped tube and universal aluminum tube according to the shape.

It is divided into seamless aluminum pipe and ordinary extrusion pipe according to extrusion method

It is divided into ordinary aluminum tubes and precision aluminum tubes according to the precision. The precision aluminum tubes

generally need to be processed after extrusion, such as cold drawing, fine drawing and rolling

By thickness: ordinary aluminum pipe and thin-walled aluminum pipe

Performance: corrosion resistance, light weight.

characteristic

It is a kind of high-strength hard aluminum, which can be strengthened by heat treatment. It has medium plasticity under

annealing, hard quenching and hot state, and good weldability of spot welding. When using gas welding and argon arc welding, the aluminum pipe has the tendency to form intergranular cracks; The machinability of aluminum tube after quenching and cold work hardening is still good, but it is not good in annealing state. The corrosion resistance is not high. Anodizing and painting methods or adding aluminum coating on the surface are often used to improve the corrosion resistance. It can also be used as mold material. Advantages of aluminum tubes: First, welding technology advantages: the welding technology of thin-walled copper and aluminum tubes suitable for industrial production, known as a world-class problem, is the key technology of replacing copper with aluminum for the connecting tubes of air conditioners.

Second, the advantage of service life: from the perspective of the inner wall of the aluminum tube, because the refrigerant does not contain water, the inner wall of the copper-aluminum connecting tube will not be corroded.

The third is the advantage of energy conservation: the lower the heat transfer efficiency of the connecting pipe between the indoor unit and the outdoor unit of the air conditioner, the more energy saving, or the better the heat insulation effect, the more energy saving.

Fourth, excellent bending performance, easy to install and move.

.png) info@baowusteel.net

info@baowusteel.net.png) Room 1201-2232,Floor 12,Chenjing Building(Yizhongbao Industrial Park), Hedong District,Tianjin

Room 1201-2232,Floor 12,Chenjing Building(Yizhongbao Industrial Park), Hedong District,Tianjin