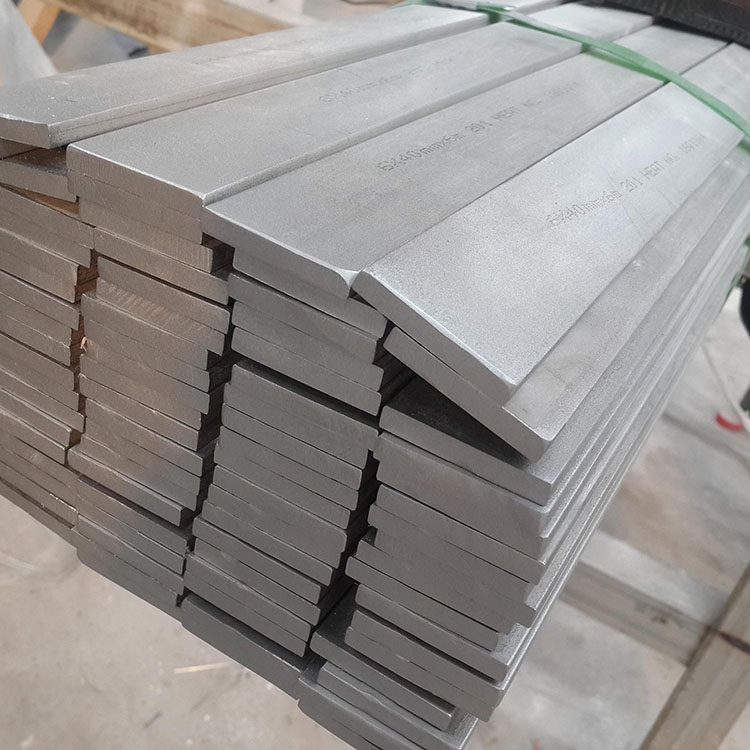

Flat Bar

Stainless steel flat bars are of rectangle shape with root face (or round edges) and they can be semi-finished or finished products in light of applications. In terms of processing technology, there are cold drawn stainless steel flat bars and hot rolled stainless steel flat bars. In terms of surface treatment, SS flat bars have polished finish and sand blast finish. In case of order, dimension, finish, quantity and other technical requirements such as annealing, solution treatment should be clearly stated. Stainless steel flat bars are widely employed in building structures and engineering structures like house beams, bridges, power transmission tower, hoisting and conveying machinery, shipyards, industrial furnace, reaction tower, containers and warehouse shelves, fences, power transmission ships, vehicles etc.

Tolerance for Hot Rolled Flat Bars

| Size | Tolerance Rank | ||

| Group 1 | Group 2 | Group 3 | |

| >7 ~ ≤20 | ±0.25 | ±0.35 | ±0.40 |

| >20 ~ ≤30 | ±0.30 | ±0.40 | ±0.50 |

| >30 ~ ≤50 | ±0.40 | ±0.50 | ±0.60 |

| >50 ~ ≤80 | ±0.60 | ±0.70 | ±0.80 |

| >80 ~ ≤110 | ±0.90 | ±1.00 | ±1.10 |

>110 ~ ≤150 | ±1.20 | ±1.30 | ±1.40 |

Tolerance for Hot Forging Flat Bars

| Size | Tolerance Rank | |

| Group 1 | Group 2 | |

| >50 ~ ≤60 | +1.5 -1.0 | +2.0 -1.0 |

| >60 ~ ≤80 | +2.0 -1.0 | +2.5 -1.0 |

| >80 ~ ≤100 | +2.5 -1.0 | +3.0 -1.0 |

| >100 ~ ≤120 | +2.5 -1.5 | +3.0 -1.5 |

| >120 ~ ≤140 | +3.0 -1.5 | +3.5 -1.5 |

| >160 ~ ≤180 | +4.0 -2.0 | +5.0 -2.0 |

| >180 ~ ≤200 | +5.0 -2.0 | +6.0 -2.0 |

| >200 ~ ≤220 | +5.0 -3.0 | +6.0 -3.0 |

| >220 ~ ≤240 | +6.0 -3.0 | +7.0 -3.0 |

| >240 ~ ≤250 | +7.0 -3.0 | +8.0 -3.0 |

| >250 ~ ≤300 | +8.0 -3.0 | +9.0 -3.0 |

Tolerance for Cold Drawn Flat Bars

| Size | Tolerance Rank | |||||

| H8 | H9 | H10 | H11 | H12 | H13 | |

| 3 | 0 ~ -0.014 | 0 ~ -0.025 | 0 ~ -0.040 | 0 ~ -0.060 | 0 ~ -0.100 | 0 ~ -0.140 |

| >3 ~ ≤6 | 0 ~ -0.018 | 0 ~ -0.030 | 0 ~ -0.048 | 0 ~ -0.075 | 0 ~ -0.120 | 0 ~ -0.180 |

| >6 ~ ≤10 | 0 ~ -0.022 | 0 ~ -0.036 | 0 ~ -0.058 | 0 ~ -0.090 | 0 ~ -0.150 | 0 ~ -0.220 |

| >10 ~ ≤18 | 0 ~ -0.027 | 0 ~ -0.043 | 0 ~ -0.070 | 0 ~ -0.110 | 0 ~ -0.180 | 0 ~ -0.270 |

| >18 ~ ≤30 | 0 ~ -0.033 | 0 ~ -0.052 | 0 ~ -0.084 | 0 ~ -0.130 | 0 ~ -0.210 | 0 ~ -0.330 |

| >30 ~ ≤50 | 0 ~ -0.039 | 0 ~ -0.062 | 0 ~ -0.100 | 0 ~ -0.160 | 0 ~ -0.250 | 0 ~ -0.390 |

| >50 ~ ≤80 | 0 ~ -0.046 | 0 ~ -0.074 | 0 ~ -0.120 | 0 ~ -0.190 | 0 ~ -0.300 | 0 ~ -0.460 |

Delivery State

| Delivery State Choice | Surface Condition |

Forged | |

| Hot Rolled | Pickled |

Sand Blasting | |

| Cold Drawn | Bright |

| Note: 1. If you require different deliver state than the above listed, kindly confirm with us. 2. In case of any enquiry or order, please kindly let us know any extra requirement not indicated here. | |

Specifications

• Dimension:

Thickness: 0.5mm - 200mm

Width: 1.5mm - 250mm

• Delivery State: Cold Drawn, Hot Rolled, Flat Bar Cut from Strip or Plates, Grinding, Forged, Centerless Grinding

• Finish: Pickled ,Bright, Polishing, Mirror, Hairline

• Hot-selling Products:

a. Stainless Steel Hot Rolled Flat Bar

b. Stainless Steel Pickeld Flat Bar

c. Stainless Steel Cold Drawn Flat Bar

d. Stainless Steel Polished Flat Bar

Standards

ASTM A276, ASTM A484M, DIN174, EN 10278

Features

Anti-corrosion (the degree is susceptible to the alloys contained), heat-resistance, good cold and hot working properties, good toughness, good comprehensive performances and wide application.

Applications

Home appliances, electric appliances, construction materials, medical equipment, auto parts, petroleum, chemical application, agricultural irrigation, edible oil refinery factories, paper plants, shipyard, nuclear power plant etc.

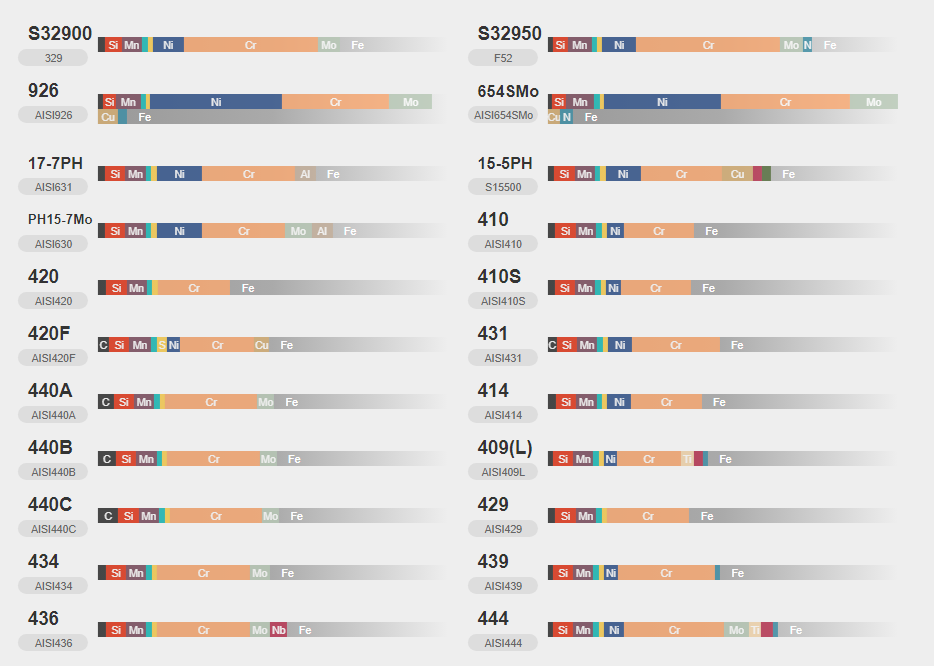

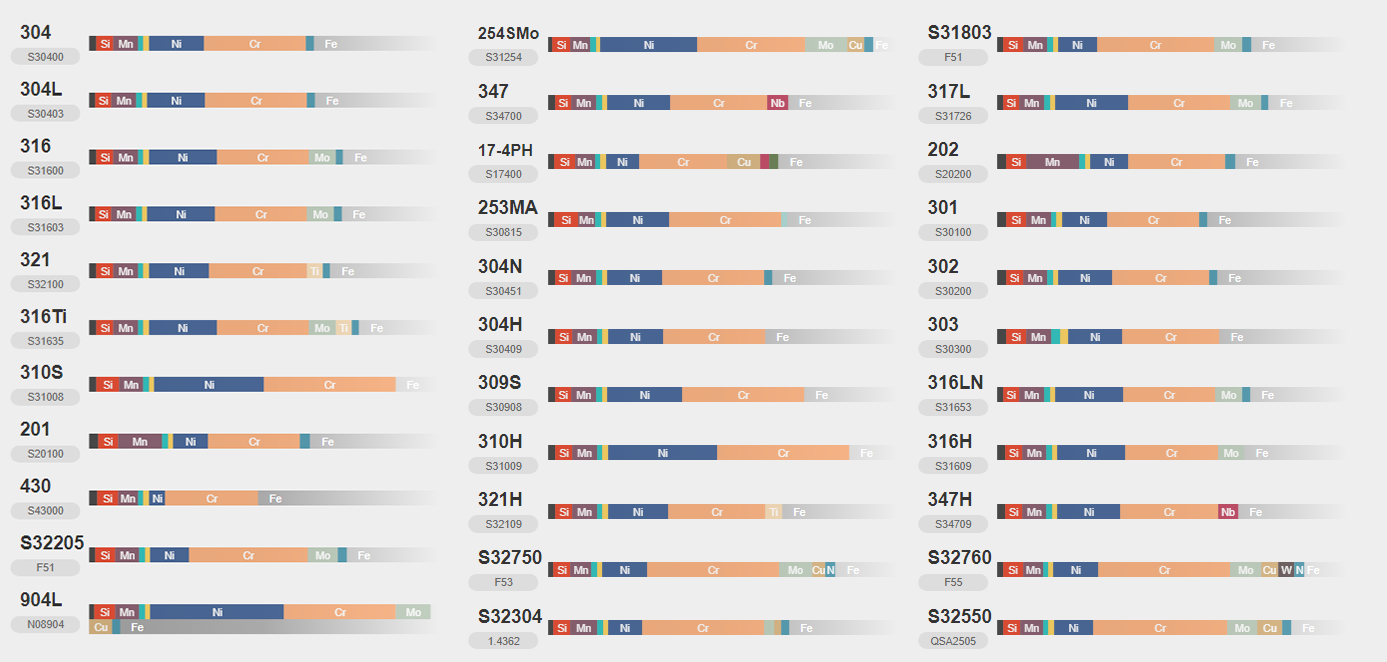

Main Grades

Austenitic Stianless Steel

Super Austenitic Stianless Steel

Duplex & Super Duplex Stianless Steel

Precipitation Hardening Stianless Steel

Ferritic Stainless Steel

Martensitic Stainless Steel

Manufacturing Process

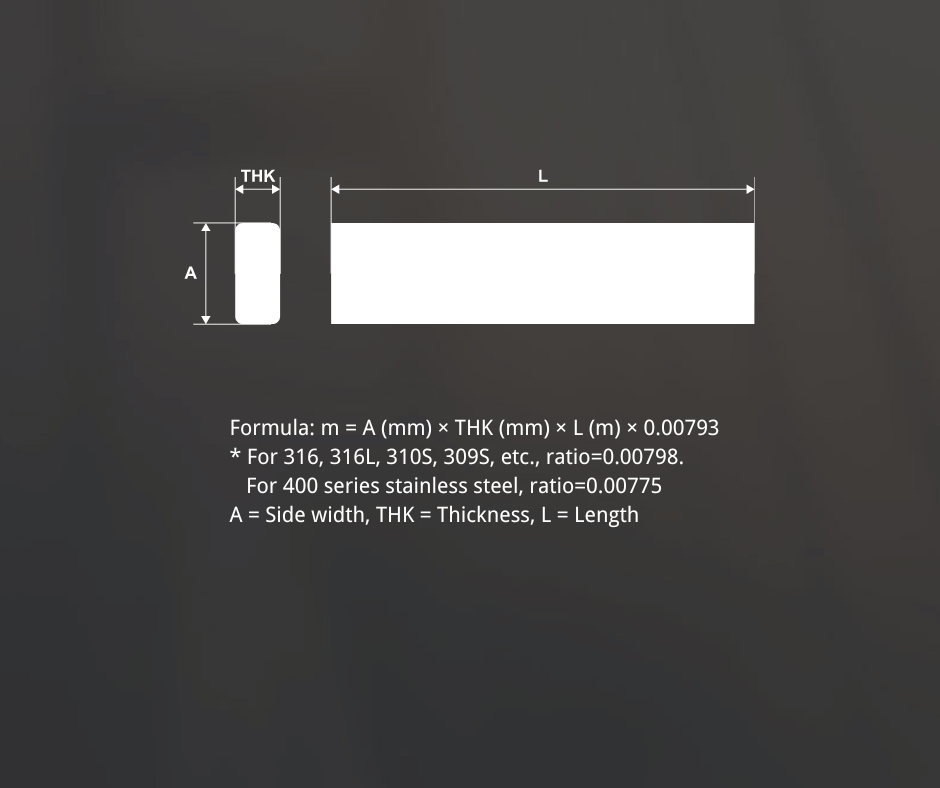

Drawing & Formula

Package

All of our stainless steel seamless pipe & tubes are packaged as per international standard to prevent any possible damage or loss. By default, we will use thick woven plastic bag to bundle the finished pipes together in batches.

All of our stainless steel seamless pipe & tubes are packaged as per international standard to prevent any possible damage or loss. By default, we will use thick woven plastic bag to bundle the finished pipes together in batches.

For some special pipes & tubes that are vulnerable to dirt, scratches, stress or rough handling, we will suggest wooden case for protection. Kindly note, wooden case can incur extra cost, not only its own cost, but also the increased freight cost, which is especially true for air transportation. For enhanced customer experience, we also provide dedicated package as per your special requirements.

For some special pipes & tubes that are vulnerable to dirt, scratches, stress or rough handling, we will suggest wooden case for protection. Kindly note, wooden case can incur extra cost, not only its own cost, but also the increased freight cost, which is especially true for air transportation. For enhanced customer experience, we also provide dedicated package as per your special requirements.

Logistics

By default, we will quote based on sea transportation, such as FOB, CFR, CIF and the like for most inquiries or orders.

By default, we will quote based on sea transportation, such as FOB, CFR, CIF and the like for most inquiries or orders.

If you have your own warehouse or freight forwarder in China, we can also transport to your designated place in China free of charge.

Quotation based on air transportation is also optional upon your request for urgent demands

FAQ

What’s the finish of your stainless steel welded pipe?

For industrial application, the finish of our stainless steel welded pipe is No.1 or pickled finish. We can also do polished SS welded pipe, like 320#, 400#, 600# or mirror finish as per your requirement. In case of enquiry or order, please also indicate which side you want to do the polishing, external, internal or both.

What is the standard length? Can I have the tubes/pipes cut into the length I want?

Our standard length of SS welded pipe is 5.8m or 6meter for most overseas orders.

Yes, we can cut pipes into the length you want, but this can incur extra cost. In case of order, please also indicate the cutting method you prefer. We have laser cutting, plasma cutting and water-jet cutting for your options.

Do you also have SS pipe fittings?

Yes, we have, like elbows, flanges, reducers, etc. For detailed information, please kindly refer to our product.

Where's your main market?

South America, South-East Asia, Middle-East, Europe and so on.

What's your package for SS welded pipe?

By default, our package is thick woven plastic bag, but we also provide wooden case or dedicated package as per your requirement. You can also refer to our pictures for better understanding.

How long is your delivery time?

Normally, it takes two weeks for us to complete production of SS welded tube for order quantity less than two containers, but the delivery time might also be influenced by other factors such as special grade, special size, large quantity of the product itself, or some force majeure.

.png) info@baowusteel.net

info@baowusteel.net.png) Room 1201-2232,Floor 12,Chenjing Building(Yizhongbao Industrial Park), Hedong District,Tianjin

Room 1201-2232,Floor 12,Chenjing Building(Yizhongbao Industrial Park), Hedong District,Tianjin