Incoloy Alloy 825

Classification :

Stainless steel plate

Keyword: Steel Plate

Incoloy 825 is a nickel iron chromium alloy, which is widely used in petroleum, natural gas and chemical processing industries. It has good corrosion resistance and can operate at higher temperatures than most stainless steels. Incoloy 825 is a completely austenitic nickel iron chromium alloy, stabilized by titanium and added with copper and molybdenum. Incoloy 825 is a general engineering alloy, which is resistant to acid and alkali metal corrosion in oxidation and reduction environments.

The Incoloy825 has the following functions:

Good resistance to stress corrosion cracking.

Good resistance to pitting and crevice corrosion

Good oxidation resistance and non oxidative thermal acidity.

It has good mechanical properties at room temperature and high temperature up to 550 ℃

Certification of pressure vessels with manufacturing temperatures up to 450 ° C

Incoloy825 metallographic structure:

Incoloy825 alloy has a stable face centered cubic structure. Chemical composition and appropriate heat treatment ensure that the corrosion resistance will not be weakened by sensitization.

Incoloy825 Corrosion resistance:

Incoloy825 is a general engineering alloy, which is resistant to acid and alkali metal corrosion in oxidation and reduction environments.

Incoloy825 is widely used in various industrial fields where the working temperature is no more than 550 ℃.

Typical applications include:

Heating pipes, containers, baskets and chains for sulfuric acid pickling plants.

Seawater cooling heat exchanger, marine product pipeline system, acid gas environment pipeline.

Heat exchanger, evaporator, washing, immersion tube, etc. In phosphoric acid production.

Air heat exchanger in petroleum refining

Food Engineering

chemical process

Flame retardant alloy for high-pressure oxygen

.jpg)

.jpg)

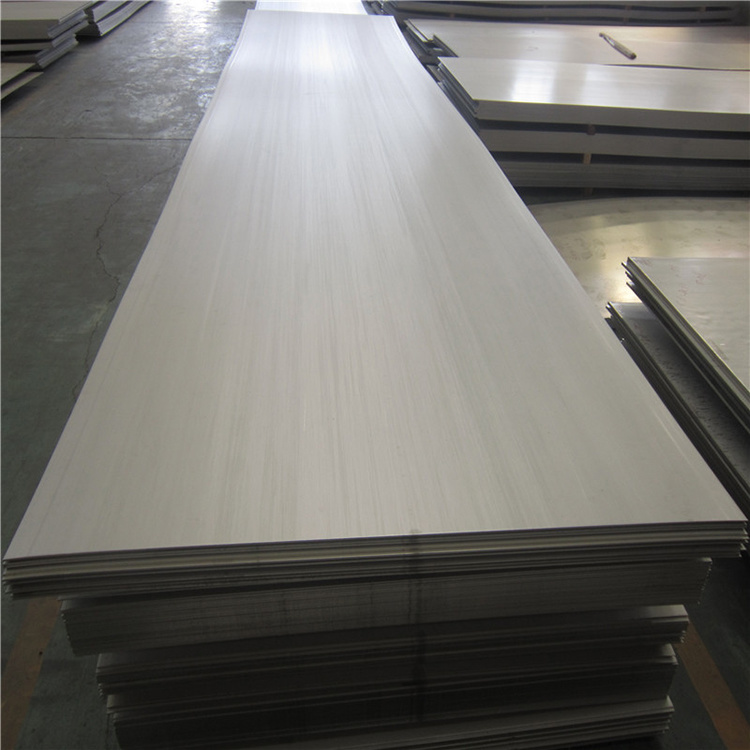

Warehouse Storage

.jpg)

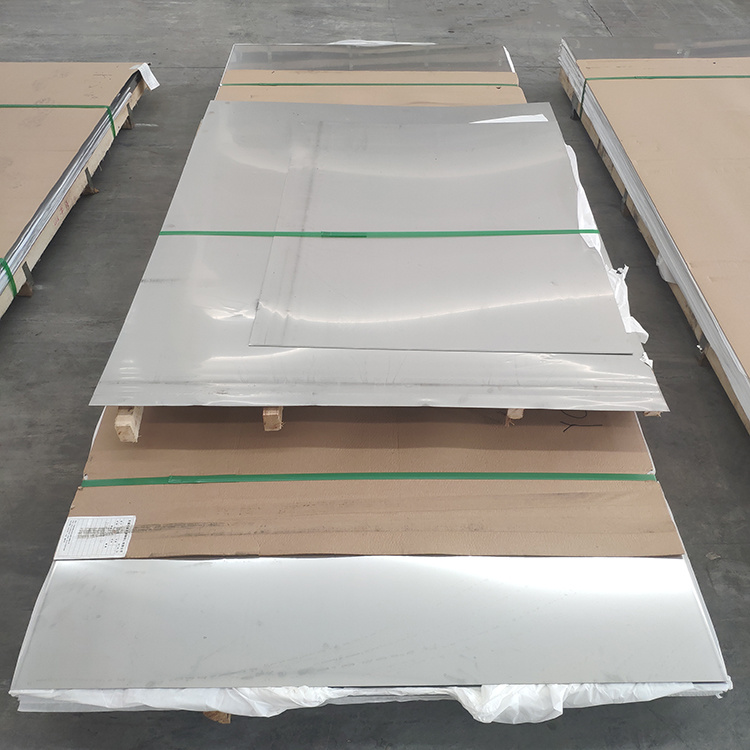

Packing and shipping

The group has 15 production lines including pickling line, cold rolling line, hot dip (thickening) galvanizing line, hot dip galvanizing line and color coating line. It can meet the annual production capacity of 1 million tons of pickling coils, 1 million tons of cold-rolled coils, 900,000 tons of galvanized and galvanized sheets, 450,000 tons of thickened galvanized sheets, and 300,000 tons of color-coated sheets.

.jpg)

Technology

.jpg)

.png) info@baowusteel.net

info@baowusteel.net.png) Room 1201-2232,Floor 12,Chenjing Building(Yizhongbao Industrial Park), Hedong District,Tianjin

Room 1201-2232,Floor 12,Chenjing Building(Yizhongbao Industrial Park), Hedong District,Tianjin