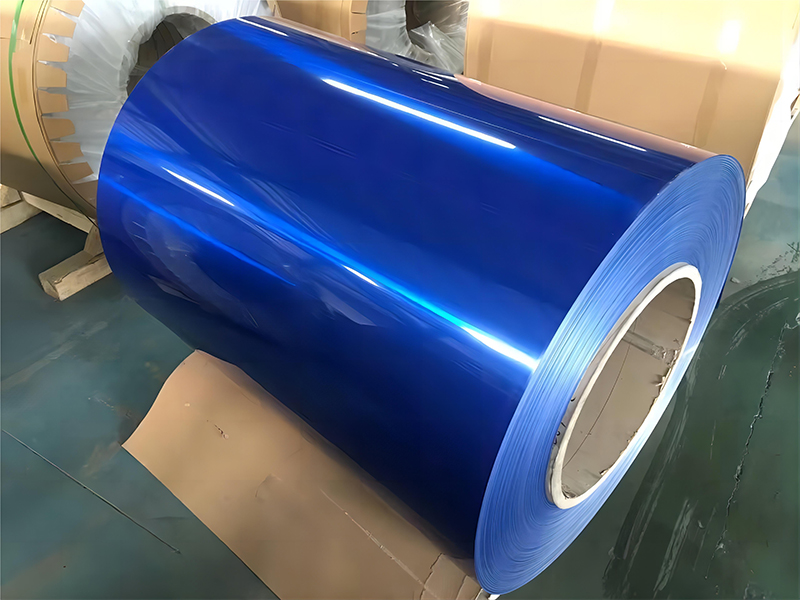

Color Coated Galvanized Steel Coil (PPGI)

thickness:0.15-2.0mm

Coil Width:600-1250mm

Color:Red,Blue,Green,White and other RAL color

| Description: | Prepainted galvainzed steel coils |

| Thinkness: | 0.2-2.0mm |

| Width: | 600mm-1250mm |

| Type of Substrate: | Galvanized Steel |

| Coil Weight: | 2-5T |

| Painted Surface: | Printing/Filmed/Matte/Wrinkled |

| Paint Top: | 15-35Microns |

| Paint Back: | 5-35Microns |

| Primer Painted: | Polyurethane /Epoxy /PE |

| Back painted: | Epoxy/Modidied Polyester |

| Top Painted: | PVDF/HDP/SMP/PE/PU |

PPGI is pre-painted galvanised iron, also known as pre-coated steel, coil coated steel, color coated steel etc., typically with a hot dip zinc coated steel substrate ;

PPGL stands for pre-painted galvalume steel, which is a kind of color-coated steel with GL as substrate .

Difference Between PPGI and PPGL

1.Different Substrates :

PPGI is short for pre-painted galvanized steel, while PPGL is short for pre-painted galvalume steel. As the name suggests, PPGI uses galvanized sheets (with a layer of zinc coating) as base metal. While PPGL is with galvalume sheet as substrate, which is coated with 55% aluminum, 43.3% zinc, and 1.6% silicon. This is the main difference between PPGI and PPGL, which will further influence their features and applications ;

2.Service Life :

As mentioned, both zinc coating and Al-Zn coating are used to protect the metal from rusting to prolong its service life. For the GI coil , the base metal will be damaged when the zinc coating is all corroded. Generally, a galvanized coil may last for 10 to 15 years. While aluminum and zinc alloy forms microscopic particle areas. The Zn-rich phase will corrode preferentially, while the Al-rich phase will corrode very slowly. So Al-Zn coating is more corrosion-resistant than zinc-coated steel coil . According to data, the service life of PPGL is 3 times longer than that of PPGI ;

3.Weight Difference :

With the same coating thickness, Al-Zn coating is lighter than zinc coating. It is because the specific weight of aluminum is lower than that of zinc. That is to say, with the same weight, Al-Zn coating can cover 3% more space than the GI sheet ;

4.Appearance Difference :

The surface of the PPGL coil is smoother than that of the PPGI coil . It is because of the better adhesion of aluminum than zinc. For the same reason, PPGL sheets can be painted directly without pre-treatment. However, it is necessary to be pre-treated for galvanized coil ;

5.Different Features :

The heat resistance of the PPGL is better than that of the PPGI . PPGL can withstand temperatures of 315 ℃. Also, PPGL have better corrosion resistance than PPGI. It is because that the dense layer made of aluminum can prevent the base metal from further eroding ;

6.Different Applications :

Both PPGI and PPGL are widely used in wall paneling and roofing. By comparison, PPGL has better resistance to corrosion, which means it is more suitable for severe outdoor environments. Also, due to its good heat resistance and good surface conductivity, it is widely used in chimney pipes, oven and lampshade, etc. However, the cut edges of PPGL are less protected. So you can use anti-rust paint or zinc-rich paint to the cut edges.

7.Different Countries :

Geographically, PPGI is suitable for hot or cold places, such as Vietnam, UAE, Saudi Arabia, Libya, Russia, Canada, Finland, etc. While PPGL is suitable for rainy areas, such as Singapore, the Philippines, Kenya, Nigeria, Malaysia, Brazil, etc.

The advantages of PPGI and PPGL :

Both PPGI and PPGL have the advantages of good formability, corrosion resistance and strong adhesion. Even if it is used for a long time in bad weather, it can maintain the novel color and luster. Has become an ideal composite material in today’s construction, light industry, electromechanical products and other industrie

.png) info@baowusteel.net

info@baowusteel.net.png) Room 1201-2232,Floor 12,Chenjing Building(Yizhongbao Industrial Park), Hedong District,Tianjin

Room 1201-2232,Floor 12,Chenjing Building(Yizhongbao Industrial Park), Hedong District,Tianjin